To be considered serious in the world of whisky, and if you want to be a true contender for making the world’s best whisky, then you need roll up your sleeves, do your research, and collaborate with the most respected leaders of the industry. Specifically, we are talking about the champion of whisky pot stills, Forsyths of Scotland.

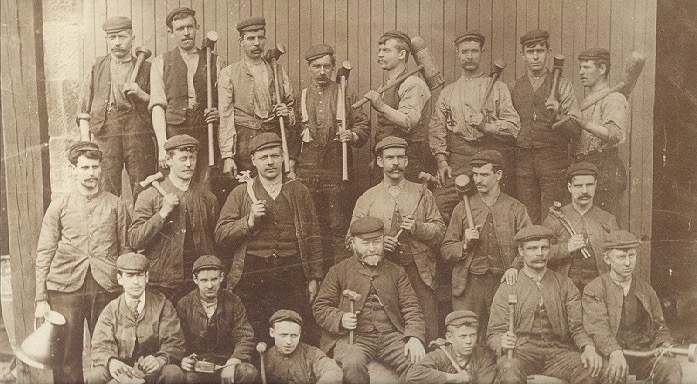

Forsyths is a name steeped in a rich history of crafting stills for the global whisky industry. Remarkably, Forsyths continues to be a family owned business, now in its 4th generation being led by Richard Forsyth. Forsyths still uses the artisanal technique of hammering (by hand!) copper sheets into the elaborate shapes needed to create the best opportunity for reflux, a process of interaction between spirit and copper that gives whisky a lot of its smoother qualities, and allows unique aromas and flavours of new make whisky to carry through the distillation process.

These handcrafting skills are married with modern technologies during the design process, showing that a company can both produce that old-fashioned excellence while still taking advantage of modernisation where it does not affect final quality.

There are very few leading distilleries in the world that Forsyths have not been involved in; you can find their stills installed all over world – including right here in China.

We engaged with Forsyths way back at the end of 2018, with our first meeting in January 2019, when we were 100% confident that Nine Rivers Distillery was “really going to be a thing.” The project had broken past the boundaries of whisky fuelled gossip and reveries. After a couple of years researching and getting more and more serious, we carved out something that resembled a real plan and were actively looking for a site for our distillery.

The History of Forsyths

Forsyths started back in 1933 by seizing an opportunity. Former coppersmith Alexander Forsyth bought out his former employer, Robert Wilson, to create Forsyth and Son. With more than 40 years experience as a coppersmith who had climbed the ranks from apprentice to tradesman to foreman, his vision took that company and elevated it to the gold standard that most whisky lovers know today.

Forsyths Asia

The Asia Pacific headquarters for Forsyths is based in Hong Kong. This HQ houses Darren Hosie, business development leader, alongside Neale Boag who leads the engineering team in the region.

Nine Rivers Distillery Version 1.0

Our early engagements with Forsyths were based on a very different concept than where we are today. Originally, Nine Rivers Distillery was more of a “proof of concept” project. This means a much smaller scale approach which is not too dissimilar to most distillery startups. We planned 2 small stills, a mash tun, some fermentors and a lot of crossed fingers. In fact, the stills from Nine Rivers Distillery Version 1.0 were less than half of the size of the smallest stills we have in our current setup: 10 stills capable of 7 million LPA.

Darren Hosie

“I’ve personally enjoyed watching this project grow and develop from a pilot plant to what will now be the biggest single malt whisky distillery in China. They will be well placed within the world rankings in terms of raw production capacity.

It’s interesting to be involved in the project as a solutions provider. The dynamics of so many people involved should be a burden to the project, but it works really well.”

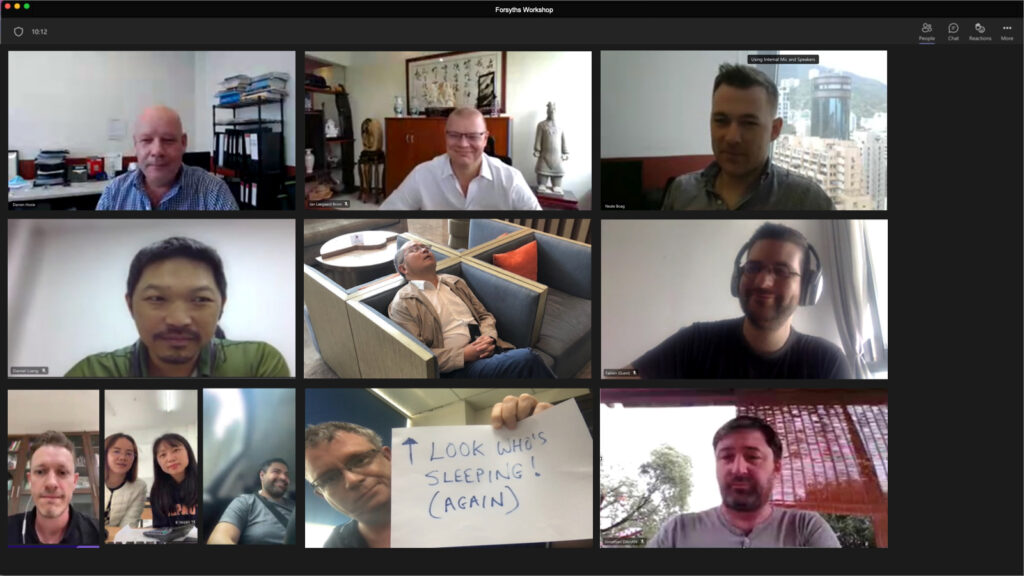

Workshops by Video Conferencing

As we all know, the global pandemic presented the world with some challenges, not least around business meetings. Just as we were ready to start workshops around still designs and still house layouts, most of us (the Nine Rivers team and, of course, Darren and Neale from Forsyths) ended up in some form of lockdown. Just like the rest of the world, we all got into the new reality of work by video conference call.

Love it or hate it, we made do. The point of the workshops was to include as many opinions and perspectives as we could with respect to how we shape our stills and the type of new make spirit we want to be crafting. As you probably saw from our last article, we had a LOT of ideas regarding what this should look like. We had some pretty amazing ideas, but our engineering wizards kept us grounded in what was possible, safe, and environmentally friendly.

We didn’t include the entire team in those workshops – let’s be fair, all that engineering stuff can get a little bit too boring (no offense, Neale). In fact, even Hayden fell asleep during most of the calls. It must have been all the running around he does…

Our Still Requirements

At the end of our workshops, we reached some agreements on what we needed from our stills. We’ll share some of those things with you all now, but we have to keep a few things under wraps at this stage – top secret and all that 007 type stuff. What we can share is this:

Diversity is key for us. From virgin oak matured whiskies all the way through to sherry cask matured whiskies. This means we need a range of different new make whiskies therefore at least three different types of spirit stills are an absolute must.

We’ll spare you the technical details, but are going to have huge wash stills. Gigantic. Not just because they look amazing, and not just because we’ll be able to say we have the largest stills in China, but ultimately because our approach to energy efficiency works better with bigger stills.

Our goal became figuring out how to arrange them in a configuration that was not only efficient for production processes, but also would look as awe-inspiring as Gaudi’s Basilica in Barcelona. While that might seem a touch arrogant, we feel confident this will become a popular photo opportunity that gets shared on social media by anyone walking through our doors.

This is possible thanks to the expert guidance of Neale Boag.

Neale Boag

“There were some interesting challenges in working with the Nine Rivers Distillery team – they really did want to have their cake and eat it too – not just in terms of the diversity of stills and whisky styles but their absolute commitment to minimising energy consumption and their environmental impact. All of this, PLUS the need for a visual “wow factor” to the entire project.

Thankfully I wasn’t alone on this; I had access to the vast experience and skills of a huge team of engineers to back me up from the Forsyths HQ in Scotland. There were not too many sleepless nights planning this project and I’m personally proud of what we are creating with the Nine Rivers Distillery team. The challenge of making it all work and the passion they had made everything feel rewarding.”

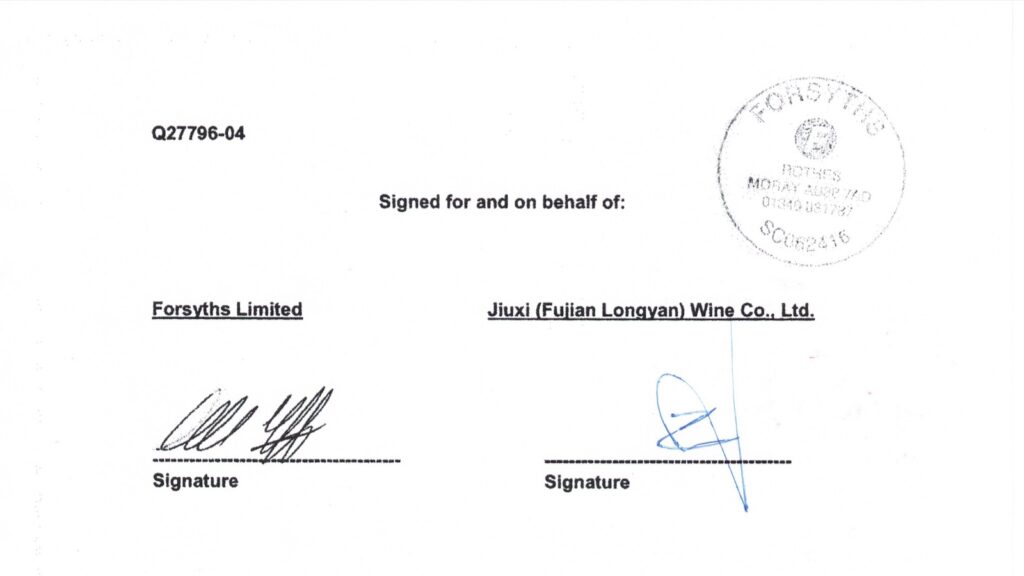

The Deal Is Done

Skip ahead a couple of years. 4 major workshops, 37 phone calls, 213 emails, and 5 company team-buildings later… we have shaken hands (virtually) and a deal is made. As these words are being typed, the manufacturing has already started at Forsyths on our first 3 of 10 stills. Soon, we will be proud parents of a 15’000 litre wash still and two 5’400 litre spirit stills.

We expect them to be arriving in China next year, in 2023, so now we have to get digging holes, pouring concrete, and laying bricks – to make sure we have a still house ready to install them in.

Would You Like To Read More?

If you enjoyed reading this, and you would like to catch up with some of our past articles, then please CLICK HERE and go to our News Section, where most of our other content is published.

Follow Us

If you have enjoyed reading this and want to learn more about Nine Rivers Distillery, then use the QR Code below to follow our WeChat Official Account.

Alternatively, if you prefer Linked In then you can CLICK HERE to follow us.

Facebook users, you can CLICK HERE.